Qingda Fein GE5050 fully automatic line ruler calibration device GE5050 series

- Prices: Request for a Quote for Further Details

- Model : GE5050

- Category: Indicator Verification Instrument

- Brand : Qingda Fein

- Delivery Time: Request for a Quote for Further Details

- Manufacturer: Qingda Fein

Products

This product consists of a high-stability grade 00 marble platform, a precise displacement drive servo system, an imported metal grating standard, a high-definition industrial digital camera, an automatic tape pressing device, an automatic tape measure retracting device (optional), and an automatic weight loading device. and online computers. When measuring the first section of the steel tape measure, manually install the steel tape measure, pull it open and fix it on the platform fixture, and then click "Start Calibration" on the computer. The automatic weight loading device and automatic tape compression device will start working. After receiving each After receiving the feedback signal from the device, the image acquisition system automatically moves to the calibration point and collects the line image. After real-time processing by the computer, the physical coordinate position of the line is identified and compared with the real-time reading of the grating to calculate the error of the measured ruler. Starting from the second section of measurement, according to the software operation prompts, install the steel tape measure head into the automatic tape measure retracting and unwinding device. The counting device and image dynamic recognition are used to accurately rewind the steel tape measure and locate the zero mark, thereby achieving the second step. Automatic measurement of error from section to whole process and full indication value. After the measurement is completed, a judgment conclusion is made according to the calculation method stipulated in the JJG4-2015 "Steel Tape" calibration regulations, and a calibration record is generated and saved in the database for users to preview and print.

The structure diagram is as follows:

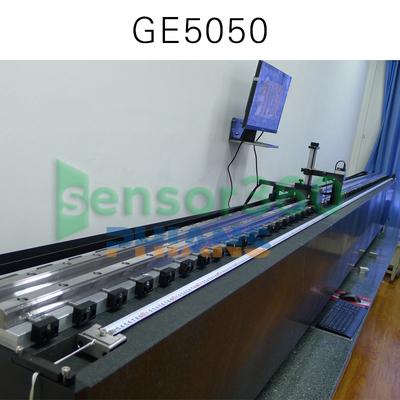

The actual objects are as follows:

Introduction

At present, domestic measurement institutions generally use the standard ruler as the length standard. They compare the steel tape measure to be inspected with the standard ruler, and perform manual line readings or use a reading microscope to obtain the line spacing error of the steel tape measure to be inspected. This calibration method is relatively primitive, has low work efficiency, high labor intensity, and is prone to visual fatigue. In order to improve measurement efficiency and accuracy, Shenzhen Fine Technology has designed and developed linear ruler calibration standard devices, GE5050 and GE5050A, based on machine vision technology and grating measurement technology in accordance with JJG4-2015 calibration regulations. Among them, the calibration range of GE5050 is 0~5 meters; GE5050A has the function of automatic segmented continuous calibration, and its calibration range is 0~100 meters. This series of products uses imported Renishaw metal gratings as the length standard, which is accurate, sensitive and stable. During the calibration process, machine vision technology is used to automatically read and identify the line scale, and automatically compare it with the grating standard displacement, eliminating the need for manual reading and recording. After the calibration is completed, the computer automatically generates a calibration report. This achieves accurate, efficient and stable fully automatic line ruler calibration. It not only improves work efficiency and reduces labor intensity, but also avoids errors caused by human factors such as misreading and misjudgment due to visual fatigue and work negligence.

Technical indicators

1. The upper limit of one measurement range (1.0~5.0)m (depends on the length of the table of the selected model);

2. Repeatability: Select new steel tapes of different specifications to be tested, repeat the measurement of a certain engraved line of each steel tape 10 times, and calculate the experimental standard deviation respectively, which shall not exceed 0.01mm;

3. Displacement speed: 300mm/second;

4. Single-point aiming time: ≤ 1.2 seconds;

5. Single point recognition speed: ≤0.2 seconds;

6. Camera picture resolution: 752*480;

7. Image magnification: ≥60 times;

According to customer requirements, it can also be customized according to the customer's actual work space conditions.