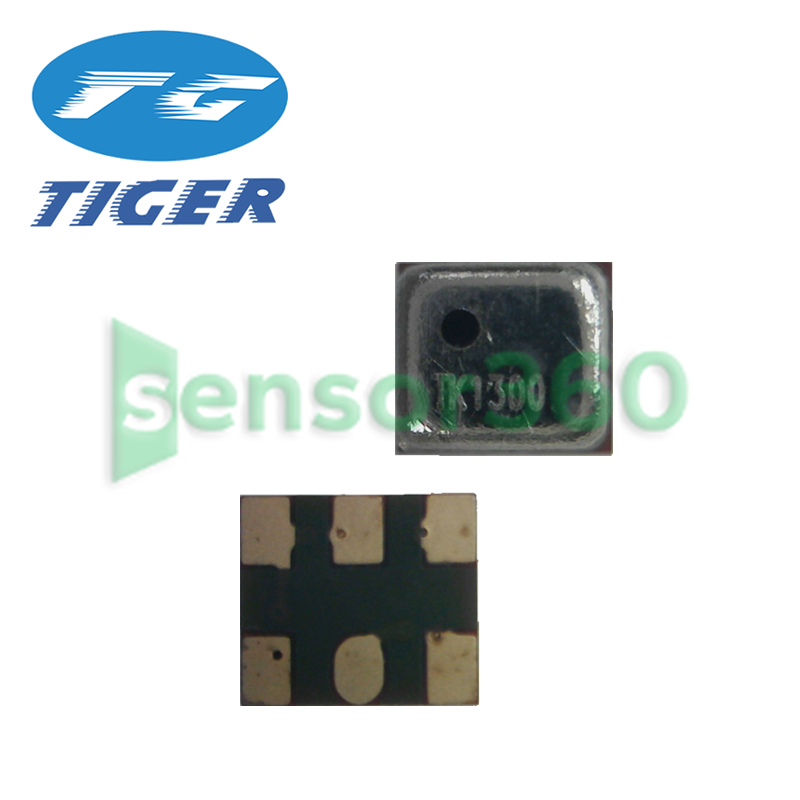

Tyco Xinyuan TK1300B pressure sensor

- Prices: Request for a Quote for Further Details

- Model : TK1300B

- Category: Pressure Sensors

- Brand : Southern Tyco

- Delivery Time: Request for a Quote for Further Details

- Manufacturer: Tyco Core

Products

TK1300B single bus digital pressure sensor

Features

Measuring range: 0~1000Kpa

Output digital signal

Collective signal collection and processing

High-precision diffused silicon pressure IC sensing chip

Temperature compensation and calibration have been completed and can be directly assembled and used.

Application areas

Rice cookers,soy milk machines,water purifiers,coffee machines and other small household appliances

Tire pressure gauge,brake assist,steering assist,MAP sensor and other automotive electronics fields

Massagers,air mattresses,gastrointestinal sensors and other medical fitness equipment fields

Instruments and other absolute pressure systems

product description

The TK1300 pressure module uses a PCB substrate,which integrates a pressure sensor chip and a high-precision circuit chip. It digitally compensates the offset,temperature drift and nonlinearity of the sensor,and uses the power supply voltage as a reference to generate a calibrated,temperature-compensated Standard signal proportional to the pressure signal.

The TK1300 pressure module is small in size,low in cost,can be SMT mounted,and is suitable for mass production.

Specifications

project | numerical value | unit |

Sensitivity | 0.1 | Kpa |

Operating Voltage | 3—3.6 | V |

Working current | ≤3 | mA |

maximum voltage | 1.5 | times rated range |

Response time | 5 | Ms |

Temperature compensation measurement accuracy | 1 | %FS |

Pressure measuring range | 0~1000 | Kpa |

Output range | 0~10000 | number |

Pressure measurement accuracy | 10 | Kpa |

Working temperature | -40~+85 | ℃ |

Overall structure and pad size

Pin definition

Precautions for use

1. Welding

Since this product has a small structure with a small heat capacity,please minimize the influence of external heat. Otherwise,it may be damaged due to thermal deformation and cause changes in characteristics. Please use non-corrosive rosin type flux. Also,since the product is exposed,be careful not to allow flux to penetrate inside.

1)Hand welding

·Please use a soldering iron with a head temperature of 260~300 °C (30 W) and perform the operation within 5 seconds.

・When soldering with a load applied to the terminals,please be careful as the output may

·Please clean the soldering iron tip thoroughly.

2) DIP welding (DIP terminal type)

·Perform the operation within 5 seconds in a DIP soldering bath with a temperature of 260°C or lower.

·When mounting on a substrate with a small heat capacity,avoid DIP soldering since thermal deformation may occur.

3)Reflow soldering (SMD terminal type)

Recommended reflow oven temperature setting conditions are as follows.

·For printed circuit board wiring,please refer to the recommended printed circuit board specifications diagram.

·Since self-calibration is not possible,please carefully align the terminals and traces.

·The set temperature is the value measured on the printed circuit board near the terminal.

·Because the tip of the pressure inlet may dissolve and deform due to high temperature due to installation,conditions,etc.,be sure to conduct a confirmation test under actual mounting conditions.

4) Correction of welding part

·Please complete the correction in one go.

·When correcting lap soldering,please use a soldering iron with a smooth head shape and do not apply additional flux.

· Regarding the temperature of the soldering iron tip,please use a soldering iron that is below the temperature stated in the specification sheet.

5) Applying excessive force to the terminals may cause deformation and impair solderability,so please avoid dropping the product or performing complicated use.

6) The curvature of the printed board should be kept below 0.05mm relative to the entire sensor,and please manage this.

7) After installing the sensor,when cutting and the substrate,please be careful not to cause stress in the welded part.

8) Since the terminals of the sensor are exposed,if a metal piece or the like touches the terminals,an output abnormality may occur. Please be careful not to touch it with metal pieces or hands.

9) After soldering,when applying coating to prevent the insulation of the substrate from deteriorating,please be careful not to allow chemicals to adhere to the sensor.

2. Cleaning

1) Since the product is an open type,please be careful not to allow cleaning fluid to penetrate inside.

2) When using ultrasonic waves for cleaning,the product may malfunction,so please avoid using ultrasonic waves for cleaning.

3. Environment

1) Please avoid using or storing the product in places where there are corrosive gases (organic solvent gas,sulfurous acid gas,hydrogen sulfide gas,etc.) that may adversely affect the product.

2) This product is not drip-proof,so please do not use it when it may be splashed with water,etc.

used in places.

3) Do not use it in an environment where condensation occurs. In addition,when the moisture attached to the sensor chip freezes,it may cause changes in the sensor output or damage it.

4) When the chip of the pressure sensor is structurally exposed to light,the output will Especially when applying pressure through a transparent cover,etc.,avoid allowing light to come into contact with the sensor chip.

5) Please avoid using methods that apply high-frequency vibrations such as ultrasonic waves.

Please confirm under actual use conditions

Since these specifications are individual product specifications,in order to improve reliability during actual use,please confirm the performance and quality under actual use conditions.

Regarding other uses

1) Pressure range and incorrect installation method may cause accidents,so please be careful.

2) The pressure medium that can be used directly is only dry air. Other,especially when used in corrosive gases (organic solvent gas,sulfurous acid gas,hydrogen sulfide gas,etc.) and con moisture or foreign matter,may cause malfunction and damage,so please avoid using it in the above environment. use.

3) There is a pressure sensor chip inside the pressure inlet. Inserting foreign objects such as needles through the pressure inlet may cause damage to the chip and blockage of the inlet,so please absolutely avoid the above operations. In addition,please avoid blocking the air inlet when using it.

4) Regarding the operating pressure,please use it within the rated pressure range. If used outside the range,damage may occur.

5) Since static electricity may cause damage,please pay attention to the following when using it.

(1) When storing,please use conductive material to short-circuit between terminals,or wrap the entire unit with aluminum foil,etc. Since plastic containers are easily charged,please do not use them when storing or transporting them.

(2) When using,please ground the charged objects on the table and the workers to safely discharge the surrounding static electricity.

6) Depending on the pressure used,please pay full attention to the fixation of the product and the casing,and the fixation and selection of the introduction tube. In addition,if you have any questions,please contact us.