Aerospace Nanyang

Company Homepage

Aerospace Nanyang (Zhejiang) Technology Co., Ltd. Located in the beautiful Deqing County in the northern suburbs of Hangzhou City. The company was founded in 1985. In the past 30 years, it has been focusing on the R&D and manufacturing of force measurement and weighing sensors and is one of the professional sensor manufacturing companies in China. The company always adheres to the concept of "keep improving" and provides high-quality products and services to the market.

The company has a professional technical team and strong technical force. It has been committed to the design and development of new products for many years and has obtained more than 10 patents. Among them, the cross-beam bridge sensor has exquisite design and high precision, and has obtained multiple patents and international certifications; the crane scale product is small in size and has high measurement accuracy. It is a revolutionary innovative product and will have a profound impact on the crane scale industry; low height and large range The load cell solves customers' stringent requirements for installation space and usage environment. The complete solutions involve various types of scales, weighing instruments and various industrial force measurement systems. Strong technical force and rich industry experience can provide customers with various weighing and force measurement solutions. The company's products can be used in various harsh industrial environments, among which the operating temperature range of high-temperature sensors can reach 250 degrees Celsius.

Rigorous technology and sophisticated equipment are the guarantee of product quality and performance. The company has introduced a number of advanced production processes at home and abroad, and after years of practice, has solidified a set of advanced sensor production processes. Among them, the vacuum heat treatment process of the elastomer makes the elastomer material more uniform; the stainless steel shot blasting process on the surface of the elastomer can effectively remove the residual stress of the elastomer and extend the fatigue life of the sensor by more than 30%; the sensor patching, bridge assembly, and sealing processes adopt domestic External strain gauges, wires, various sealants, and unique processing techniques are used to produce sensors with high precision, stable performance, and long service life.

The company covers an area of 35 acres, with a construction area of more than 24,000 square meters. It has more than 200 various machining centers and CNC processing equipment (including more than 20 machining centers, 1 vacuum heat treatment equipment, and 1 stainless steel shot blasting machine), and more than 100 various types of measurement and testing equipment (including 1,000-ton Hydraulic standard force check-in machine, a 100-ton lever machine, a 20-ton net weight machine, an 8 cubic meter high and low temperature box), complete production, measurement and testing equipment provide a solid foundation for large-scale production and product quality protection.

The company's annual output is about 500,000 pieces of various steel and aluminum sensors. The main products include 18 series of weighing, force measuring, pressure, torque, instrumentation, etc., with more than 1,000 specifications and varieties. The products can go up to the sky, into the earth, and into the sea, and can adapt to various complex and harsh temperature, corrosion, vibration and electromagnetic environments. The measuring range of the force measuring and weighing sensors is from 10 grams to 6000 tons, and the measuring accuracy is C1 to C5; the measuring range of the pressure sensor is from absolute pressure to 250MPa, and the measuring accuracy is 0.5%F.S to 0.05%F.S; the measuring range of the torque sensor It is 0.1N.m to 200000N.m, and the measurement accuracy is 0.5%F.S to 0.05%F.S. The company's products are exported to more than 40 countries and regions abroad and are widely used in weighing instruments, aerospace, petroleum, engineering machinery, testing machines, lifting machinery, industrial control and other fields.

As early as 1999, the company passed the ISO-9000 quality assurance system certification. Currently, the company has a complete quality management system and organizes production in strict accordance with the international recommendations "OIML" and the American "NTEP" product standards. A number of products have obtained "OIML", "NTEP", "IP", "CE", "RoSH" and other certifications. After years of intensive cultivation, Nanyang Sensors has become synonymous with quality products.

In December 2012, through equity transfer, the company joined forces with the China Aerospace Aerodynamics Technology Research Institute and became a high-tech company controlled by the institute, which opened up a bright road for future development. Looking forward to the future, the company will rely on its R&D and management advantages in aerospace high-tech and move towards becoming an international sensor manufacturing company. Higher, farther, stronger... What has changed is better products and services, but what remains unchanged is the concept and pursuit of excellence. Zhejiang Nanyang Sensor Manufacturing Co., Ltd. will work with you to interpret the Chinese Dream!

Contact Information

Log in to learn more Contact information

-

Address

Log in to learn more Contact information

-

Contact Email

Log in to learn more Contact information

-

Web

Log in to learn more Contact information

-

Contact Number

Log in to learn more Contact information

Product Catalog

Product Catalog

Recommended Sensors

-

MCS series

Aerospace Nanyang MCS series six-dimensional force sensor

-

HNY-DTU-600 series

Aerospace Nanyang HNY-DTU-600 series data storage remote transmission terminal

-

CG-1

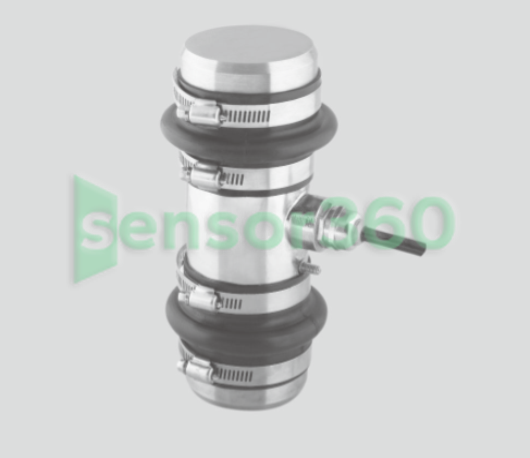

Aerospace Nanyang CG-1 column sensor

-

CP-1

Aerospace Nanyang CP-1 column sensor

-

CP-2

Aerospace Nanyang CP-2 column sensor

-

CP-3

Aerospace Nanyang CP-3 column sensor

-

CP-4

Aerospace Nanyang CP-4 column sensor

-

CP-8

Aerospace Nanyang CP-8 column sensor

-

CP-9

Aerospace Nanyang CP-9 column sensor

-

CP-11

Aerospace Nanyang CP-11 column sensor

-

CP-13

Aerospace Nanyang CP-13 column sensor

-

CP-15

Aerospace Nanyang CP-15 column sensor

-

ET-3

Aerospace Nanyang ET-3 column sensor

-

CW

Aerospace Nanyang CW column sensor

-

ET-1

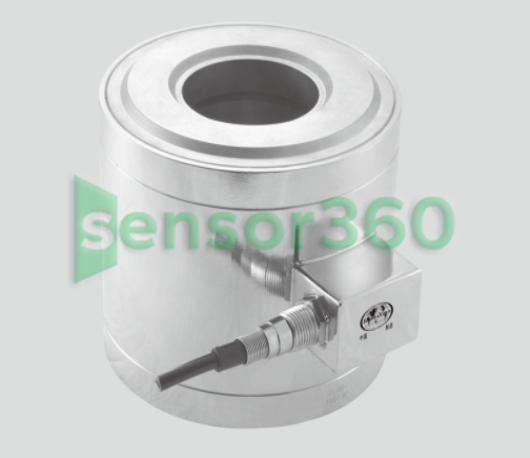

Aerospace Nanyang ET-1 crane scale sensor

-

ET-1A

Aerospace Nanyang ET-1A crane scale sensor

-

ET-2

Aerospace Nanyang ET-2 crane scale sensor

-

ET-4

Aerospace Nanyang ET-4 crane scale sensor

-

ET-5

Aerospace Nanyang ET-5 crane scale sensor

-

ET-8

Aerospace Nanyang ET-8 crane scale sensor

-

GF-1

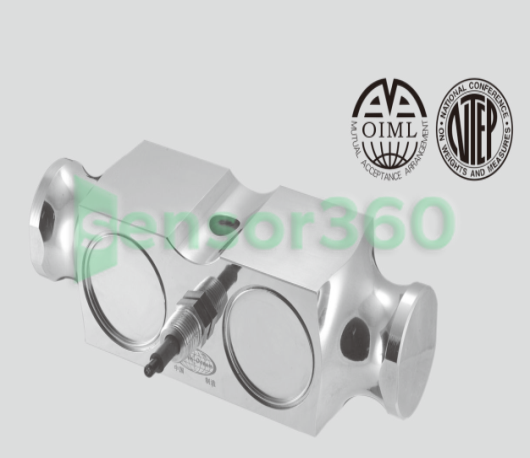

Aerospace Nanyang GF-1 double shear beam (bridge type) sensor

-

GF-2

Aerospace Nanyang GF-2 double shear beam (bridge type) sensor

-

GF-3

Aerospace Nanyang GF-3 double shear beam (bridge type) sensor

-

GF-4

Aerospace Nanyang GF-4 double shear beam (bridge type) sensor

-

GF-5

Aerospace Nanyang GF-5 double shear beam (bridge type) sensor

-

GF-7

Aerospace Nanyang GF-7 double shear beam (bridge type) sensor

-

GF-9

Aerospace Nanyang GF-9 double shear beam (bridge type) sensor

-

GF-11A

Aerospace Nanyang GF-11A double shear beam (bridge type) sensor

-

GF-11B

Aerospace Nanyang GF-11B double shear beam (bridge type) sensor

-

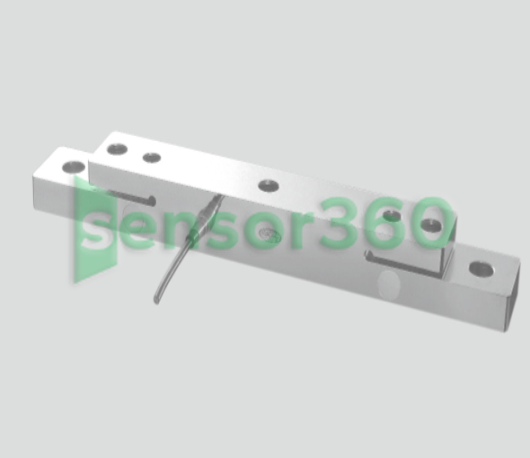

GX-1

Aerospace Nanyang GX-1 single shear beam sensor