Because most power management chips work in a small space,the conditions for heat dissipation are not good,and most of them work in a high temperature environment for a time. The power supply chip often experiences rapid temperature rise,and even experiences rapid temperature changes when the voltage is unstable. Therefore,the stability of the power supply chip during rapid temperature changes needs to be tested before leaving the factory. This is very important. America's inTEST ThermoStream high and low temperature shock testing machine provides a rapid temperature shock range of -100°C to +225°C. Suitable for high and low temperature shock testing of various power management chips.

In terms of power management chip reliability testing,America's inTEST ThermoStream ATS series heat flow meters have unique advantages that are different from traditional high and low temperature chambers:

Fast temperature rate,rapid heating/cooling of 18°C per second

ISO 9001,CE,RoHS certified

Real-time monitoring of the actual temperature of the component under test,and the impact airflow temperature can be adjusted at any time

For a single IC (module) among the many components on the PCB circuit board,high and low temperature shocks are carried out independently without affecting other surrounding components.

Meet R&D and large-scale mass production requirements

Can be used in conjunction with various testers such as Advantest,Teradyne,Verigy,etc.

| inTEST hot-selling models | ATS-545 | ATS-710E | ATS-535 |

| Temperature range °C | -75 to +225 | -75 to +225 | -60 to +225 |

| temperature rate | -55 to +125°C approx. 10 S+125 to -55°C approx. 10 S | -55 to +125°C approx. 10 s+125 to -55°C approx. 10 s | -40 to +125°C <12 s+125 to -40°C <40 s |

| air compressor | Extras | Extras | Internal integrated air compressor |

| control method | Knob type | touchscreen | Knob type |

| Gas flow scfm | 4 to 18 | 4 to 18 | 5 |

| Temperature display and resolution | +/- 0.1°C | ||

| Temperature accuracy | 1.0°C (when calibrated to NIST standards) | ||

High and low temperature shock test cases for power management chips:Power chips used in the consumer electronics industry. The picture below shows the actual power chip under test,soldered on the PCB board. The temperature test needs to be performed with power on.

The test temperature range is - 60℃ - 150℃,and 12 sets of different cycle temperature settings are carried out.

Model used: inTEST ATS-545

Power management chip high and low temperature shock test case:

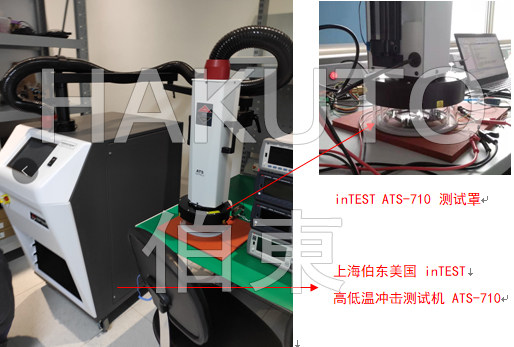

For power management chips used in the automotive electronics industry,during electrical testing,a tester is also used to set different temperature values to check whether the functions of the power chip are normal at different temperatures. By using the American inTEST heat flow meter,a significant Improve work efficiency and be able to promptly assess potential problems in the R&D process.

Test temperature range: -40℃ - 80℃

Model used: inTEST ATS-710E

Power management chip high and low temperature shock test case:

The power management chip used in the power system was unable to use an air compressor due to limited R&D space of the customer. Finally,the ATS-535,the world's only high and low temperature impact machine with an internal integrated air compressor,was selected for testing.

Test temperature range: -60℃ - 150℃

Model used: inTEST ATS-535

Power Management Integrated Circuits are chips that are responsible for the conversion,distribution,detection and other power management responsibilities of electrical energy in electronic equipment systems. In the design of power supplies,various forms of management chips are needed. In electrical testing As the temperature of the power supply changes,it is necessary to ensure the normal operation of the chip. Generally,the higher the temperature of the chip,the lower the reliability and the higher the failure rate. Therefore,temperature issues must be considered at the beginning of the chip design.

Since its establishment in the 1970s,inTEST Thermal Solutions in the United States has more than 50 years of R&D and production experience. After years of market practice,it has achieved high reliability and stability,meeting the testing requirements of various electronic chips. inTEST has acquired Thermonics and Temptronic. is an American company inTEST general agent.

In view of the confidentiality of customer information,if you need further information or discussion about inTEST high and low temperature impact testing machine,please refer to the following contact information:

(same number on

Some brands are now looking for cooperative agents. If you are interested,please contact Ms. of at

All rights reserved by,any copying will be prosecuted!

0/300